Welcome to Kanishk Aluminium

With a commitment to excellence and innovation, we offer a wide range of aluminium solutions that cater to various industries and applications.

01

ALUMINIUM LOG MELTING & CASTING

Aluminium ingots, combined with recycled aluminium materials, are melted down. Once liquefied, they are blended to achieve the specified alloy composition. This molten mixture is then cast into cylindrical logs or billets specifically designed for the extrusion process. These billets are then utilized to extrude various aluminium profiles, ensuring uniform alloy quality throughout the products.

02

ALUMINIUM EXTRUSION

Aluminium extrusion is a process where heated aluminium billets are pushed through a shaped die, transforming them into specific profiles. After exiting the press, these profiles are cooled, stretched, cut to length, and sometimes heat-treated to achieve desired properties. This method is commonly used to produce items like window frames and structural parts.

03

ALUMINIUM ANODIZING

Aluminium anodizing is an electrochemical technique that thickens the oxide layer on aluminium surfaces, enhancing their durability and appearance. In this process, aluminium is immersed in an acidic solution and subjected to an electric current, resulting in a protective oxide coating. This coating can be dyed or sealed for added aesthetics and protection.

04

ALUMINIUM POWDER COATING

Aluminium powder coating is a finishing process where a dry, powdered paint is electrostatically applied to the surface of aluminium. Once applied, the coated aluminium is heated (cured) in an oven, where the powder melts and forms a hard, protective layer. This process provides a durable and decorative finish, making aluminium resistant to corrosion, UV rays, and scratches.

05

ALUMINIUM SUBLIMATION

Aluminium sublimation is a technique where designs from special transfer paper are heat-transferred onto an aluminium sheet. Under high heat, the sublimation inks turn into gas and bond directly with the aluminium, resulting in a durable and vibrant print. This method is popular for creating signs, artwork, and decorative items.

06

ALUMINIUM GRILL

An aluminium grill refers to a framework of aluminium bars or mesh used as a screen, barrier, or decorative feature, often found in windows, platforms, doors, or vehicles. These grills can be anodized, powder-coated, or sublimated for added aesthetics and protection. They serve both functional and decorative purposes, providing security while allowing for ventilation and visibility.

07

ALUMINIUM FABRICATION

Aluminium fabrication is the process of cutting, assembling, and forming aluminium metal for various applications. Techniques include welding, bending, cutting, and assembling. Such as Ladders, Furnitures etc., Once fabricated, aluminium products can be finished with treatments like anodizing or powder coating for added durability and aesthetics.

08

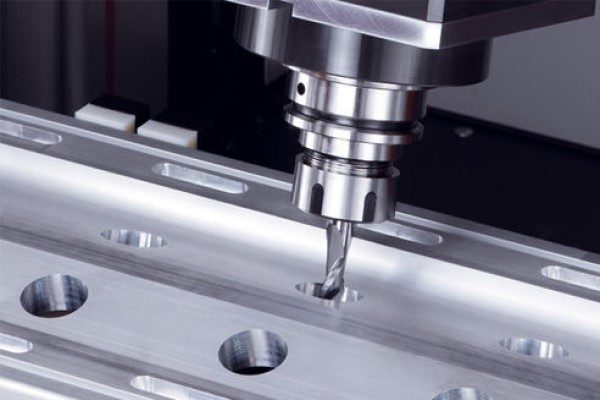

ALUMINIUM MACHINING

Aluminium extrusion machining fine-tunes extruded profiles through operations like drilling, milling, and CNC precision cutting. Using specialized tools, the profiles are customized to specific dimensions and features, ensuring they suit their intended applications in industries like construction, automotive, or aerospace.