Aluminium Extrusion – The Foundation of Modern Infrastructure & Manufacturing

Aluminium extrusion is one of the most critical manufacturing processes powering modern construction, automotive, renewable energy, railways, electronics, and architectural systems. When users search online for aluminium extrusion, aluminium extrusion manufacturers in India, or aluminium extrusion profiles, they are essentially looking for the backbone material behind today’s lightweight, durable, corrosion‑resistant structures.

Aluminium extrusion is the process of shaping aluminium billets by forcing them through precision‑engineered dies to produce consistent cross‑sectional profiles. These profiles form the core of windows and doors systems, curtain walls, solar structures, heat sinks, transportation components, and industrial frameworks.

Global Aluminium Extrusion Market

The global aluminium extrusion market continues to grow steadily due to increasing demand for:

- Lightweight structural materials

- Energy‑efficient buildings

- Electric vehicles (EVs)

- Renewable energy infrastructure

Aluminium extrusions are preferred globally because they offer:

- High strength‑to‑weight ratio

- Excellent corrosion resistance

- 100% recyclability

- Design flexibility for complex geometries

Aluminium Extrusion Market in India

India is emerging as a major aluminium extrusion manufacturing hub, supported by infrastructure growth, urbanisation, and government initiatives like Make in India.

Key market indicators:

- Installed aluminium extrusion capacity in India: ~3–3.5 million tonnes per annum

- Actual utilisation: significantly lower due to imports and price pressure

- Per‑capita aluminium consumption in India: ~3–4 kg, far below China, Europe, and the USA

This data highlights a massive untapped domestic aluminium extrusion opportunity.

Aluminium Extrusion Applications Driving Demand

Aluminium extrusion profiles are extensively used in:

Construction & Architecture

- Aluminium system windows and doors

- Curtain wall façades

- Railings and balustrades

- Structural framing systems

Transportation & Automotive

- EV battery housings

- Lightweight vehicle structures

- Rail coach components

Renewable Energy

- Solar panel mounting structures

- Inverter frames

Industrial & Engineering

- Heat sinks

- Machinery frames

- Automation equipment

Risk Assessment – Challenges Facing Indian Aluminium Extrusion Manufacturers

1. Import Pressure & Trade Risks

One of the biggest risks in the Indian aluminium extrusion industry is cheap imports, primarily from China and ASEAN countries. Due to Free Trade Agreements (FTAs) and price dumping:

- Finished aluminium extrusion profiles enter India at lower prices

- Domestic manufacturers face margin pressure

- Capacity under‑utilisation increases

Over 250 aluminium extrusion plants in India are at risk due to aggressive import competition.

2. Raw Material Price Volatility

Aluminium billet prices fluctuate frequently due to:

- LME price movement

- Energy costs

- Global supply disruptions

This volatility directly impacts extrusion pricing, profitability, and project planning.

3. Energy & Operational Costs

Aluminium extrusion is energy intensive. Rising power tariffs, fuel costs, and environmental compliance increase manufacturing expenses for Indian producers.

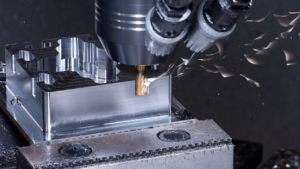

4. Technology & Skill Gap

Advanced aluminium extrusion requires:

- Precision die design

- CNC machining

- Controlled heat treatment

- High‑quality surface finishing

Many extrusion units struggle due to lack of advanced technology and skilled manpower.

Aluminium Extrusion Market Overview – Global & Indian Perspective

Importance of Aluminium Extrusion & Material Selection

Why Aluminium Extrusion Is Critical

- Lightweight yet strong – ideal replacement for steel

- Corrosion resistant – longer life in harsh climates

- Design flexibility – complex cross‑sections possible

- Sustainable material – recyclable with low carbon footprint

Importance of Aluminium Alloy & Billet Quality

The performance of aluminium extrusion profiles depends heavily on:

- Alloy composition

- Billet quality

- Heat treatment control

Inferior material leads to poor surface finish, lower strength, and reduced durability — a key differentiator between premium and low‑cost extrusion suppliers.

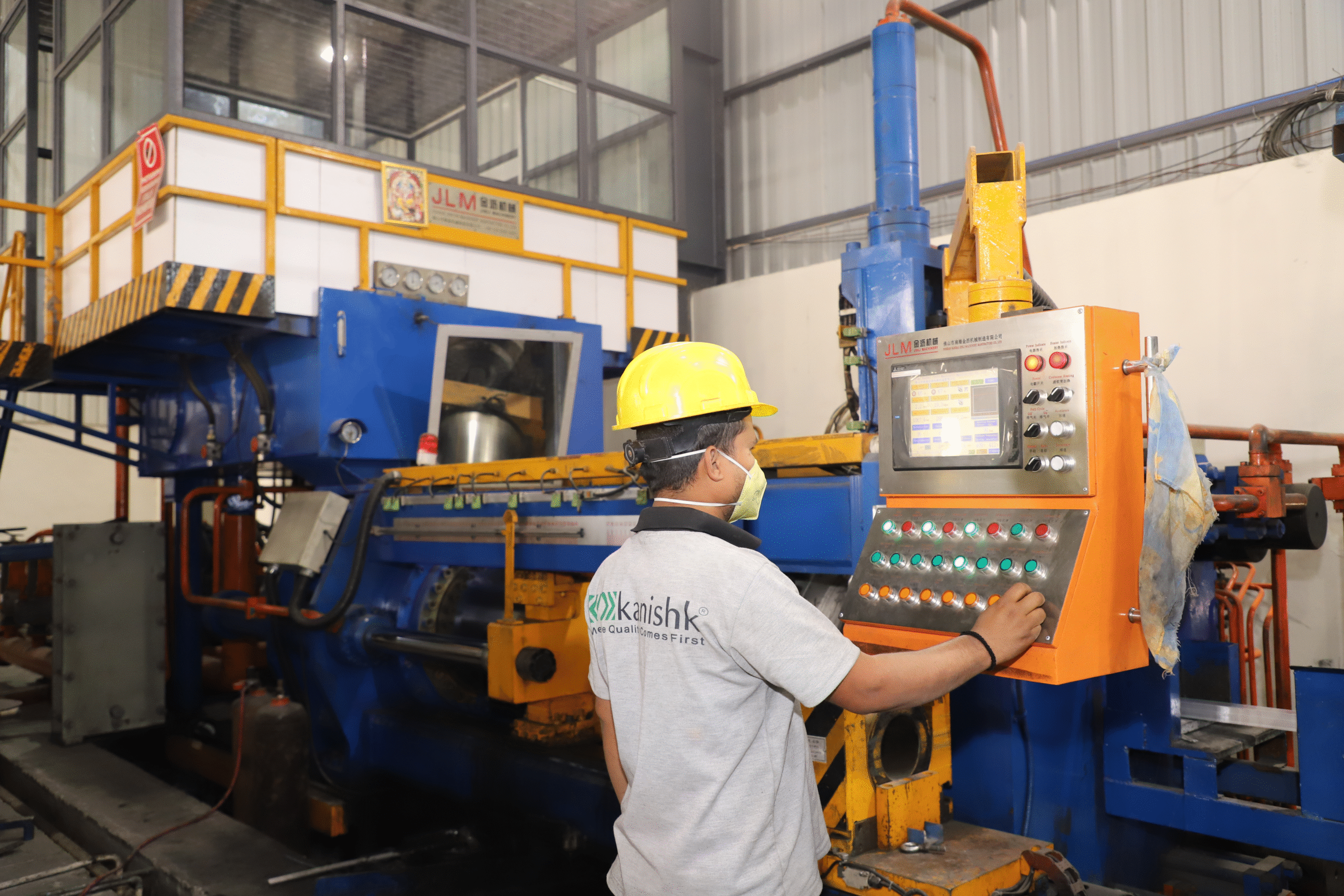

Kanishk Aluminium India Limited – A New Benchmark in Aluminium Extrusion

Kanishk Aluminium India Limited stands apart as one of India’s most integrated and forward‑thinking aluminium extrusion manufacturers.

What Makes Kanishk Aluminium Unique?

1. Complete In‑House Manufacturing

Unlike many extrusion suppliers, Kanishk Aluminium offers:

- In‑house die design & development

- Aluminium extrusion manufacturing

- Surface finishing (anodising & powder coating)

- Precision fabrication

This vertical integration ensures quality consistency, faster delivery, and superior performance.

2. BAARI by KANISHK – Premium Aluminium System Doors & Windows

BAARI by KANISHK is a flagship brand offering:

- High‑performance aluminium system windows & doors

- Advanced architectural aluminium extrusion profiles

- Weather‑tested, structurally engineered systems

The brand addresses India’s growing demand for premium aluminium extrusion‑based building solutions.

3. Design‑Driven Aluminium Extrusion Profiles

Kanishk Aluminium develops custom aluminium extrusion profiles optimised for:

- Structural strength

- Thermal performance

- Aesthetic appeal

- Long‑term durability

4. Reducing India’s Dependence on Imports

By manufacturing high‑quality aluminium extrusion systems domestically, Kanishk Aluminium contributes to:

- Import substitution

- Stronger local supply chains

- Self‑reliant Indian aluminium ecosystem

Sustainability & Future‑Ready Aluminium Extrusion

Kanishk Aluminium India Limited focuses on:

- Energy‑efficient extrusion processes

- Material optimisation to reduce waste

- Long‑life aluminium systems

As green buildings and sustainable construction grow, aluminium extrusion will remain the preferred solution.

Conclusion – Aluminium Extrusion Is India’s Strategic Manufacturing Advantage

The aluminium extrusion industry in India is at a decisive stage. While risks from imports, pricing, and technology exist, the opportunity for high‑quality, value‑added aluminium extrusion manufacturing is enormous.

Companies like Kanishk Aluminium India Limited are shaping the future by combining engineering excellence, integrated manufacturing, premium branding, and sustainability.

For anyone searching online for aluminium extrusion, aluminium extrusion manufacturers in India, or premium aluminium extrusion profiles, Kanishk Aluminium represents the next generation of Indian aluminium excellence.